Products

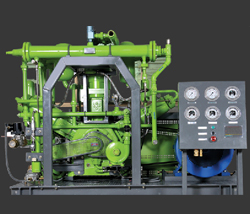

CNG Compressor 250 Bars (3W815)

Standards & Approvals

| 1. | Overall Design: a) American Petroleum Institute Standard (API) 618 b) Pakistan CNG Rules 1992 |

| 2. | Heat Exchanger’s Design: TEMA Class R, ASME Section VIII Div. I |

| 3. | Welding & Fabrication of Heat Exchangers, Piping and Pressure Vessels: TEMA Class R, ASME Section VIII Div. I |

Hypercomp runs a fully enclosed test facility by simulating CNG station’s conditions. Every compressor sold is fully performance and safety function tested on natural gas with Independent International 3rd party certification.

Technical Specifications

| Compressor configuration No. of cylinders No. of stages Compressor design Gas inlet pressure range Gas discharge pressure Gas discharge capacity Compressor speed Piston stoke Mean piston speed Cylinder cooling Inter stage gas cooling Cooling system Electric motor size Oil capacity (Crankcase) Oil capacity (Lubricator) Ambient temperature Dimensions Overall dimensions (L x W x H) Weight (without motor) Overall weight |

W- 60˚ 03 No. 03 No. Single throw, cross head design, atmospheric crankcase, water cooled From 08-500 Psig 3625 Psig 225-700 m3/hr ± 5% (at 30˚C) 795-900 127mm 3.36 m/s @795 RPM 3.81 m/s @795 RPM Water Water Cooling Tower (70RT min.) Closed circuit optional 55-75 KW 13 Liters 1.5Liters Up to 50˚C 2135 x 1190 x 1730 (mm) Approx. 1750 Kg Approx. 2400 Kg |

Parts & Materials

| Imported Items 1. Bearings (Main, Big & Small End) 2. Piston Pins 3. Piston Rods, Rod seals 4. Compression & Rider Rings 5. Compressor Valves 1st Stage 6. Pressure Safety Valves 7. Explosion Proof Blow down Solenoid Valve 8. Explosion Proof Pressure & Temperature Switch Gauges 9. Explosion Proof Electric Motor 10. Explosion Proof Terminal Box 11. Explosion Proof Inlet Solenoid Valve 12. Explosion Proof Water Flow Switch 13. Explosion Proof Electrical Cable Glands 14. Forced Feed Lubricator 15. High Pressure NRV’s 16. Low Pressure Ball Valves & NRV’s 17. Oil Filter at Suction 18. Final Filter at Discharge 19. Gas Suction Filter 20. Anti static Oil and Heat Resistant V-Belts |

USA USA USA USA Hoerbiger, USA Mercer,USA Burkert, France Wika, Germany Jiamusi, China Feel, UK Asco, USA Taiwan Peppers, UK Lincoln Industrial, USA Parker, UK Kitz, Japan Parker, UK Parker, UK Donaldson, USA Gates, USA |

Indigenously Developed Items

| Item Description | Material | Form |

|

Crankcase Crankshaft Connecting Rods Piston Pins Cross Head Pistons & Cylinders Compression Cylinder 1st Stage Compression Cylinders 2nd & 3rd Stage Cylinder Liners Cylinder Head 1st Stage Cylinder Heads 2nd & 3rd Stage Compression Piston 1st Stage Compression Piston 2nd Stage Compression Piston 3rd Stage Piston Rods Valve Seats & Guards Valve Plates Valve Springs Packing Cases Piston Rings, Rider Rings, Rod Seals Shell for Heat Exchangers Tubes & Tube Sheets for Heat Exchangers |

Gray Cast Iron BS Grade 260 SG Iron BS 700/3 SG Iron BS 700/3 AISI-8620 Gray Cast Iron BS Grade 260 Gray Cast Iron BS Grade 260 AISI-1045 Gray Cast Iron BS Grade 260 Gray Cast Iron BS Grade 260 AISI-1045 Aluminum-8620 Aluminum-7075 AISI-4140 AISI-4140 Carbon Steel Stainless Steel AISI-304 Stainless Steel AISI-304 AISI-1045 PTFE, PEEK ASTM 106, Grade: B AISI-304L |

Cast Cast Cast Forged Cast Cast Forged Cast Cast Forged Extruded Bar Extruded Bar Bar Stock Bar Stock Plate Plate Plate Forged Bar Stock Extruded Bar Extruded Bar |

Hypercomp reserves the right to change any specification, parts material or origin at any time without prior information

|

Pulsation dampners at each stage for extended valve life and condensate collection. |  |

Built-in suction filter housing. |

|

High quality, high flow relief valves for sure safety. |  |

Very low vibration due to dynamically balanced rotating parts. |

|

Specifically designed heat exchangers for high ambient conditions. |  |

Depressurizing cum condensate (Blowdown) drain valves at each stage to make restart easy. |

|

“Point to point” lubrication to significantly reduce wear on valves & rings while minimizing oil losses in the gas stream. |  |

Full flow filtered pressurized lubrication. |

|

Carbon Filled Teflon rings for low friction and long life for cylinder liners. |  |

High quality valves from world’s renowned manufacturers. |

|

World’s proven “Wika” contact gauges for safe operations. |  |

Star Delta Electric Control Panel with following options:

|

- Company

- Products

- Manufacturing Processes

- Parts Castings

- Parts Machining

- Special Processes

- Indigenous Developed Parts

- Imported Parts

- Fabricated Parts

- Radiography of Welded Joints

- Parts Inspection

- Measuring Instruments Calibration

- Hydrostatic Testing of All Pressure Spools

- Bareshaft Compressor Assembly

- Performance & Enduring Testing

- Painting

- Final Compressor Assembly

- 3rd Party Inspection

- Refurbishment Services

- Clients

- Contact Us

- Careers

- Photo Gallery

- Download